- #NCPLOT CONVERT NC TO FOR FREE#

- #NCPLOT CONVERT NC TO MANUAL#

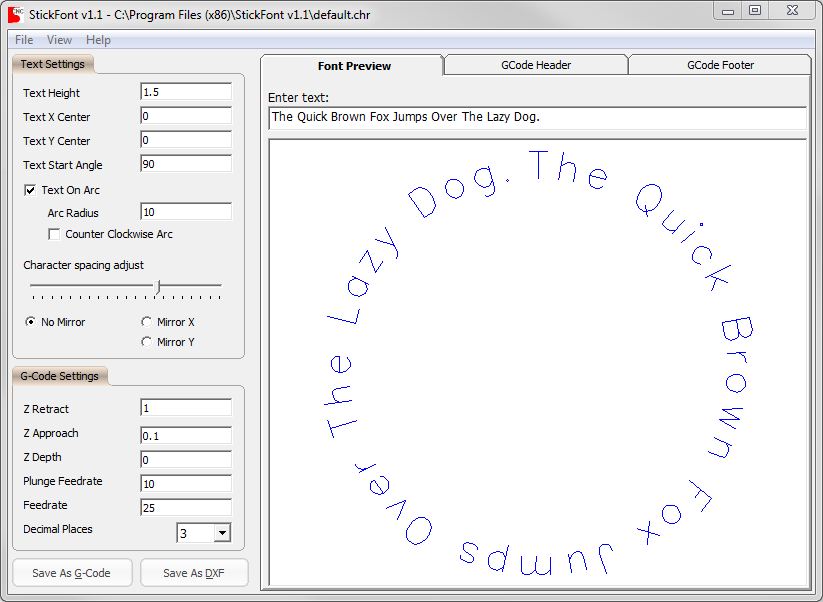

- #NCPLOT CONVERT NC TO SOFTWARE#

- #NCPLOT CONVERT NC TO SERIES#

Lathes use different programing format and some different G-Codes, the basic G-Codes a lathe use's is the same, so if you interest is in Lathes then you should learn Lathe ProgramingĪnything you learn in classes programing by hand is good for understanding what each code does, and can help when looking at a program made in Cam Software, learning Cam software also can be very beneficial if you want to work with CNC machines Programing is a must Thank you again for your help.G-Code is a standard that will work for almost all machines, so the machines your friend has will use the same codes as a Haas, the only differences are some have a different format but the same codes don't change the way the machine will run all you need is to look at the format he is using and you will see the same codes being used it is only ( text ) and you can write it using Notepad save it and run it in a machine control He uses AutorCad (I think) and something else. I talked with a friend who runs a machine shop which has a couple CNC Mills (not Haas) so my programs wouldn't run there and he said that he had not written a G code program in a bunch of years, if ever. I have thought about getting a CNC Lathe which would be more useful to me than a Mill.

I am taking the class for "fun" so I don't know how much of this I will ever use.

It's over in a few weeks though and after that.

#NCPLOT CONVERT NC TO MANUAL#

My class is manual G code programming, so that is what I am doing. I started "making things" on a manual mill and lathe so CNC and G code is a huge step up, but writing G code is certainly not anywhere near the top of the mountain. Unfortunately, I agree with you are am sure you are correct.

#NCPLOT CONVERT NC TO FOR FREE#

Haas has a good diagram in their manual comparing G70, G71, and G72 here: I don't know what is commonly used, but I would think that G72 is more commonly used than G71 since it drills a full circle of holes.When it gets down to what do most people use, is there Cam software and would not use any of these G70 G71 or a G72 to do there Hole patterns they are there for hand coders but is very inefficient way to program, it is 2021 I have not used any of these codes in the last 15 years, so in reality this is a worthless exercise, unless you don't have any type of cam software, which some you can get for free not very good, but get the job done for anything like this Haas has a good diagram in their manual comparing G70, G71, and G72 here: I don't know what is commonly used, but I would think that G72 is more commonly used than G71 since it drills a full circle of holes. The command puts the mill at the center of the pattern prior to drilling the bolt circle which is one of the requirements for issuing the G70 command. You are of course correct that the L0 doesn't drill the hole, which is intentional. I apologize if my terminology isn't quite correct. The Haas manual shows G70 as a "Bolt Hole Circle", G71 is a "Bolt Hole Arc", and the G72 code "Bolt Holes Along an Angle".

#NCPLOT CONVERT NC TO SERIES#

The initial program had a series of holes in a line (G72) and then a bolt circle (G70). With G0, the hole placement shows up but the holes are not drilled. As you can see in the attachment, without G0, the commands are pretty much ignored. In the last example, I am running pretty much using just G70, inside a G82 canned cycle to produce several bolt circles. This thread has drifted a little and the commands I am running in the later examples are not just G70 and G72.

0 kommentar(er)

0 kommentar(er)